Curbmaster CM-6000

Price:

US$ 15,900.00 / unit

Note: We reserve the right to change the price without notice.

Product Details

- International Market Export: Yes

- Local Malaysian Market: Yes

Manufactured By:

Mach Robotics

Selangor, Malaysia

+6 016-677 8469 or Email

[email protected]

Contact Hours:

10am - 5pm GMT +0800

Curbmaster CM-6000 Product Information

Introduction

The Curbmaster CM-6000 is a globally recognized model of commercial kerbing machines. It is fast, compact & robust curbing machine which provides high ram compaction rate, ensuring quality kerbs for each commercial project.

Features

-

2-Man Machine Operation

Operating CM-6000 requires only 2 operators: first operator to control CM-6000, and second operator to feed concrete mix to CM-6000 Mould Hopper. Truck feeding is also possible with CM-6000, due to CM-6000's low height design.

-

500 Linear Meter Extrusion per Day

CM-6000 provides 500 linear meter extrusion distance in a typical 8 hour job, including preparation and lunch breaks.

-

Max. Mould Size up to 1.2 metres width

CM-6000 supports interchangable moulds of various designs from 175mm up to 1200mm mould width. For mould widths greater than 1200mm, please contact us for Curbmaster CM-6000X Version.

-

Comes with One Free Kerb Mould Set

CM-6000 allows interchanging of moulds on the job site itself. You can order moulds of various kerb shapes from our mould selections, or to your preference from us. Along with the mould, we will provide string line assemblies, mould finishing & cutting tools according to the mould design. Send us the mould dimensions during the order and we will send to you, preinstalled unto CM-6000.

-

Powered by Honda / Briggs & Straton Petrol Engine

CM-6000 uses high efficiency, low-fuel consumption, low-maintenance OHV(overhead valve) engines made by Honda or Briggs & Straton, delivering 20HP of engine torque to power steering hydrauclics and eccentric ram compaction system.

-

Easy-to-Source Replacement Parts

CM-6000 uses high efficiency, low-maintenance OHV(overhead valve) engines made by Honda or Briggs & Straton, delivering 20HP of engine torque to power steering hydrauclics and eccentric ram compaction system.

-

Manufactured with Absolute Precision

All Curbmaster models are precisely manufactured with CNC Cutting, Milling & Lathe Systems, ensuring consistent quality among all Curbmaster parts and components.

Back to Top

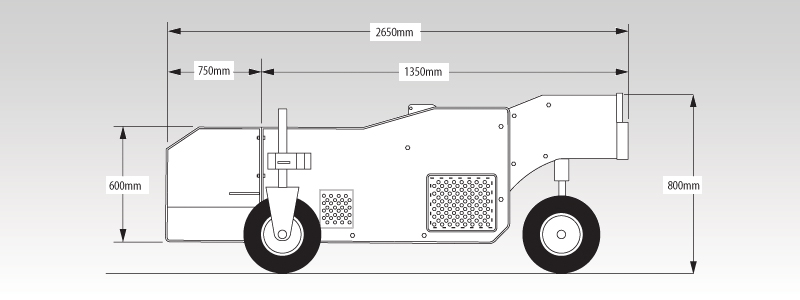

Below are the technical specifications for Curbmaster CM-6000.

| Specification | Description |

|---|---|

| Make/Model | CM-6000 |

| Brand | Curbmaster |

| Manufacturer | Robotshop DSP Sdn. Bhd. |

| Engine | 20HP Briggs & Straton / Honda Petrol Engine |

| Engine Starter | Electric Key Start Ignition |

| Wheel Steering Control | Left/Right Hydraulics Steering |

| Wheel Height Control | Individual Wheel Up/Down Hydraulics Lifting |

| Hydraulic Pump | Variable Displacement Axial Piston Pump |

| Drive | Duplex Chain Drive |

| Compaction Method | Dual Arm Eccentric Ramming System |

| Minimum Kerb Radius | ?.? metres |

| Min. Curb Size (W x H) | 175mm x 175mm |

| Max. Curb Size (W x H) | 600mm x 450mm |

| Max. Pavement Size (W x H) | 1220mm x 100mm |

| Extrusion/Laying Speed | 500 linear metres/day Per day is estimated at 8 effective working hours, including preparation. |

| Ram Stroke / Min. | Max. 25 |

| Petrol Tank Capacity | 8.5 litres |

| Hydraulic Tank Capacity | 6.5 litres |

| Slurry Coating Mix | Yes, in front of mould |

| Fuel Consumption | Approx. 2.6 liters / hr |

| Result Accuracy | ± 3 to 5mm |

| Machine Length (Without Mould) | 1900mm |

| Machine Length (With Mould) | 2650mm |

| Machine Width | 800mm |

| Machine Height | 800mm |

| Packing Size (W x L x H) | 100mm x 2850mm x 1000mm |

| Approx. Weight (with Mould) | 1200kg |

| Material Feeding Technique | Shovel Feeding s/ Truck Feeding |

| Body | Removable side & top Cover for ease of servicing. |

| Moulds | Bolt on moulds to customer specification. |

| Mould Changing Time | Approx. 35 minutes |

| Consumables | Petrol, Hydraulics Oil, Gear Oil, Engine Oil, Grease, 12V Vehicle Battery |

| Accessories | String line assembly, finishing tools, cutting tools |